Who we are

Bristol born and made to stand out, Butcombe Brewing Co. began life at a time of cultural, social and political change, crafting beer before ‘craft beer’ was even a thing.

You see, at that time, no one was risking it all starting a brewery, making simple, premium, easy-drinking ale. To do so was an act of defiance. Or madness. But, over 45 years later and a lot of hard graft, by staying true to our beliefs and Bristolian roots, it looks like owning a resolutely maverick brewing company isn’t such a crazy idea after all. By going against the grain, to work intimately with it, we made our own statement with every pint. And what was true then is just as important today.

We’re made of different stuff at Butcombe. We’re an eclectic bunch of passionate people, all brought together by our love of food, drink and service. We get the greatest buzz from seeing customers enjoying the food and drink we’ve made and served with love. Everything we do is from the heart…

Brewing Process

1. Mashing

The first step in the beer-making process is mashing, in which the grist, or milled malt, is transferred to the mash tun. Mashing is the process of combining the grist and water, also known as liquor, and heating it to temperatures usually between 100 degrees Fahrenheit up to 170 degrees Fahrenheit. Mashing causes the natural enzymes in the malt to break down starches, converting them to sugars, which will eventually become alcohol. This process takes place in one to two hours. Mash temperatures can be gradually increased or allowed to rest at certain temperatures, choices which are very much part of the brewer’s art.

Different temperature levels activate different enzymes and affect the release of proteins and fermentable sugars. Proteins play a smaller role but are important to the creation of foam in a finished beer. For heating, most brewers use steam.

2. Sparging

Sparging is the process of rinsing the spent grain with heated water to get as much of the sugars as possible from the remaining grain for the wort.

After sparging, the spent grain is commonly recycled as feed for cattle and pigs, or can be used to make bread.

3. Boiling

Once a brewer has wort, it is sterilized through a boiling process in a brew kettle, which halts enzyme activity and condenses the liquid. During the boil, which typically lasts from 60 to 120 minutes, hops are added.

4. Hopping

The qualities of aroma, taste and bitterness that hops impart to beer depend on what point they are added. Hops can be added early in the boil for bittering, with more time boiled resulting in more bitterness. They can be added mid-boil for flavor, or late boil for flavoring and aroma.

The key to hops' bitter taste in beer is alpha acids (aka humulones). These alpha acids vary in content depending on the hop variety. When exposed to the boil, alpha acids undergo isomerization, resulting in the formation of different forms of humulones. It's these iso-alpha acids that are responsible for the distinctive bitterness found in beer.

Hops can also be added at stages after the boil during whirlpooling (flavor/aroma), fermentation (dry-hopping for aroma) or maturation (dry-hopping for aroma).

5. Whirlpool

Once the boil is complete, the whirlpool phase further clarifies the wort by removing protein and hop solids through settling. These solids are known as trub. Although the boiling kettle can also be used as a whirlpool, many brewers use a separate, specially designed container.

A hop back is a type of vessel for whirlpooling that employs fresh hop flowers or cones in a sealed chamber for filtering the trub, which adds more hop aroma compounds to the wort. A hop back is often employed when whole hop cones are used in the boil. A standard whirlpool is better at collecting trub created from hop pellets.

Next, a heat exchanger is used to reduce the wort to the temperature desired for fermentation. Water heated by this exchange is often used by brewers to start a new brewing cycle.

6. Fermentation

Wort is transferred to a fermentation vessel and the yeast is pitched, or added. Ale yeast rises to the top of the wort and lager yeast generally collects in the bottom. This stage is the primary fermentation - the conversion of sugars to alcohol and carbon dioxide that lead to an ale or a lager, depending on the type of yeast used. (Hybrid beers also use one of these two types of yeast.)

Once yeast has been pitched at proper temperature, the beer is generally maintained from 60 to 68 degrees Fahrenheit for ales, and 50 degrees Fahrenheit for lagers. The process of the yeast converting sugars to alcohol generates heat and is monitored closely by brewers. The higher temperatures employed for ale yeast result in more esters, or fragrant organic compounds.

7. Racking

Racking involves transferring beer from the primary fermenter, leaving behind the yeast sediment. If the beer remains on this yeast layer for too long, the dead cells could decompose, leading to off-flavours in the beer—a phenomenon known as autolysis.

8. Packaging

After the beer has been conditioned and matured, it moves to the final stage in the production process: packaging.

We transport our beer in a sterilised tanker to our bottling plant where it is packaged and ready to ship to our customers.

9. The Serve

All the hard work has been done! Now it's up to you to enjoy your well earned pint at home or in your favourite pub or bar. Cheers!

Award Winning

Our history

1978

The late summer of 1978

Simon Whitmore founds Butcombe Brewing Co. using his Courage Western redundancy payment to convert his farm buildings and family home into a brewery.

The brewery equipment, purchased from Allied Breweries surplus plant in Burton-on-Trent, is driven back to Bristol in Simon’s Bedford 35cwt truck.

1982

Butcombe Expansion!

Butcombe Brewery is extended, taking capacity up to 5,760 pints per brew.

2005

Relocation & New Water

Butcombe Brewery relocates to a brand new site at nearby Wrington, with brewing commencing on February 26th.

The team dig a borehole deep into the ground to access the finest Mendip Spring water and slowly expand their range – crowd favourites like Butcombe Blonde, Mendip Spring and Brunel Atlantic; icons of a bygone era.

2011

Time to Collaborate

Sustainable and passionate farmer Adam Henson begins collaborating with Butcombe.

His Cotswold-grown Maris Otter malting barley produces a stunning pale ale, and we dedicate a beer to his farm - Rare Breed Pale Ale. It has gone on to win several Taste Of The West Gold Medals.

2016

Shaping The Future

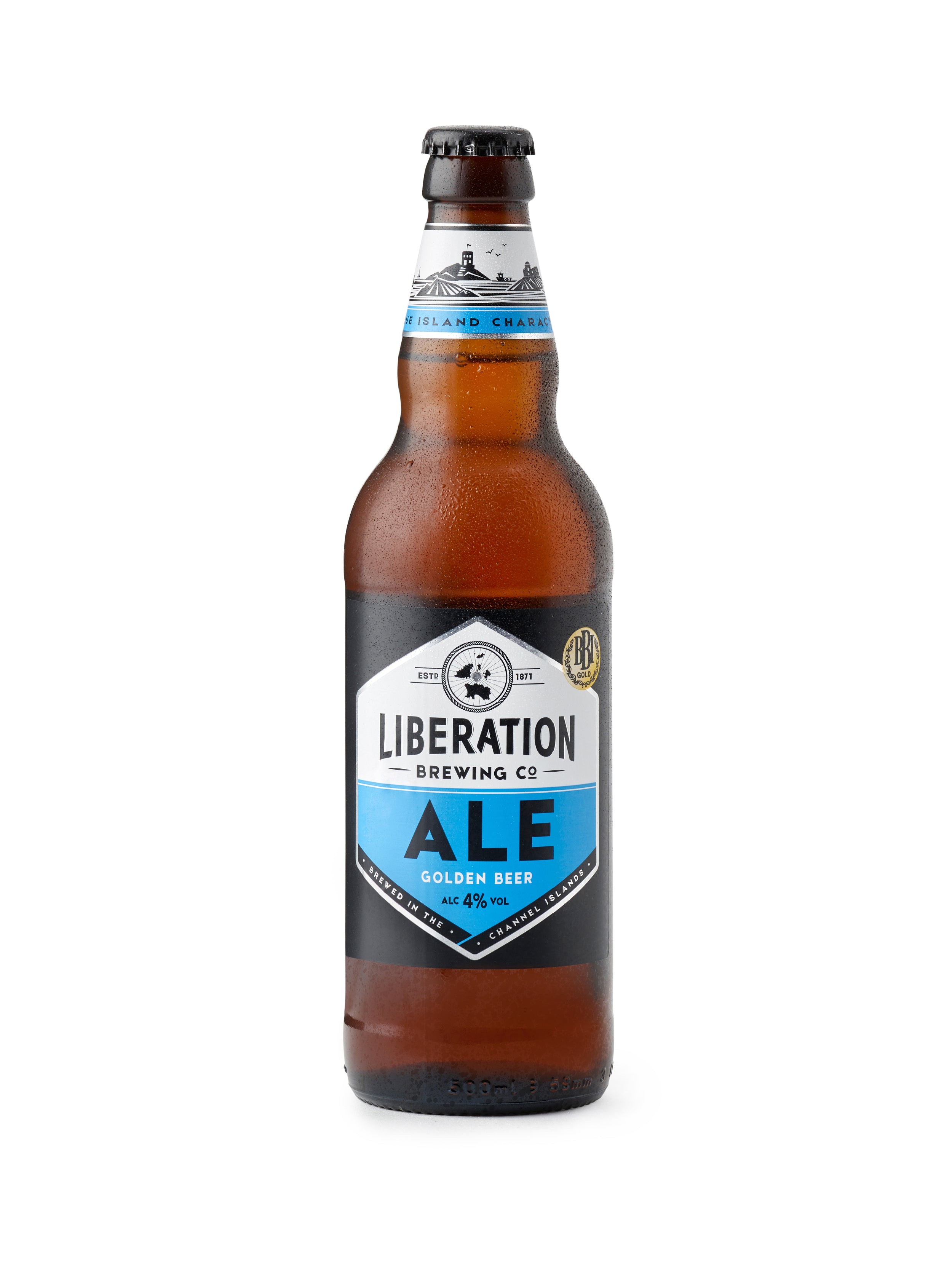

Liberation Group acquires Butcombe, merging two of the most successful independent national breweries.

2018

A New Site!

Butcombe opens a state-of-the-art bottling, kegging and distribution depot in Bridgewater.

Located near the M5 it allows ease of distribution for Butcombe beers. Beer is delivered as fresh as the day it was brewed.

2019-2020

Medal Winners

Butcombe Original and Goram IPA win Gold medals at the British Bottlers Institute Awards.

Original goes on to win Gold in the SW category at the SIBA National Beer Awards. Stateside IPA is launched, an American-inspired IPA, winning Gold at the Taste Of The West Awards.

2022-2023

More Medals!

Goram IPA Zero is launched and achieves Gold at the World Beer Awards, along with Country Winner.

Tall Tales Pale Ale is launched.

Goram IPA Zero wins Gold at World Alcohol Free Awards. Tall Tales wins Silver at the World Beer Awards.

2024

Who we are today?

We are a modern brewer with heritage from Bristol. Born at a time of cultural, social and political change we have stayed true to our independent roots and proudly brew some of the South Wests best loved beers.